Related Products

Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

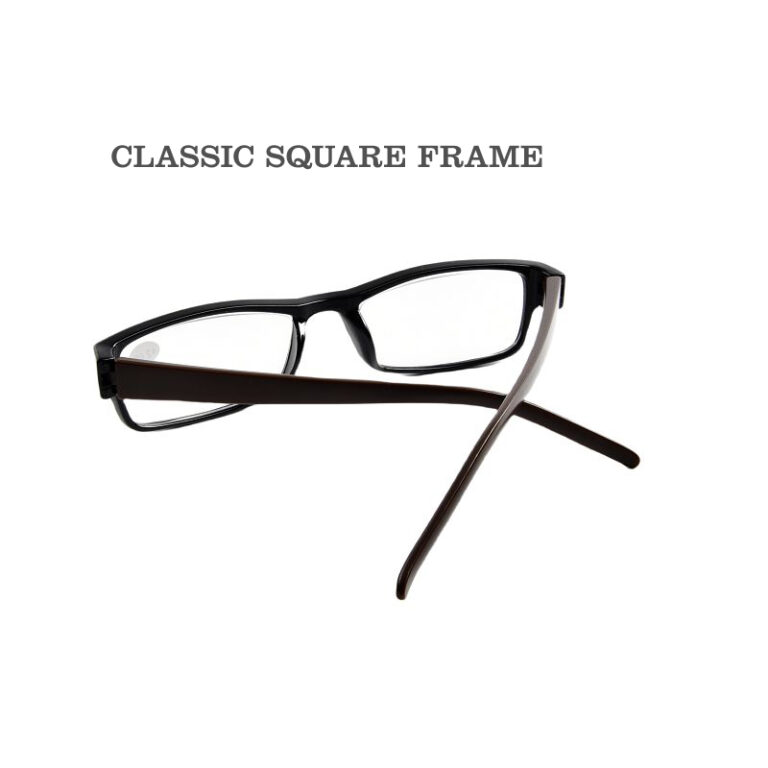

Custom square frame reading glasses offer an optimal blend of functionality, aesthetics, and customization tailored to meet diverse consumer needs. Designed with precision and engineered for comfort, these medium-sized frames integrate lightweight materials, ergonomic design, and precise optical features. Their suitability for wholesale, OEM, and ODM applications further amplifies their appeal in the eyewear industry, meeting both large-scale production and individualized customization demands.

The custom square frame reading glasses are meticulously designed to ensure both style and comfort. Below is a breakdown of their key measurements:

| Component | Specification |

|---|---|

| Frame Width | 138 mm |

| Bridge | 18 mm |

| Lens Width | 53 mm |

| Lens Height | 28 mm |

| Temple Length | 134 mm |

| Weight | 19.5 g |

The lightweight nature of the polycarbonate frame (19.5 g) ensures prolonged wearability without discomfort, while the full-rim square design complements a variety of face shapes, providing both functionality and a stylish look.

These frames are engineered to support a wide range of optical requirements. Key optical specifications include:

| Optical Feature | Details |

|---|---|

| PD Range | 62 mm ± 1 mm |

| Prescription Range | -11.00 to +8.00 |

| Progressive/Bifocal | Not Available |

| Reader Compatibility | Yes |

| Prism Adjustment | Yes |

The inclusion of prism adjustments ensures accurate alignment for users requiring specialized optical correction, while the wide prescription range enhances versatility, making these frames suitable for a large demographic.

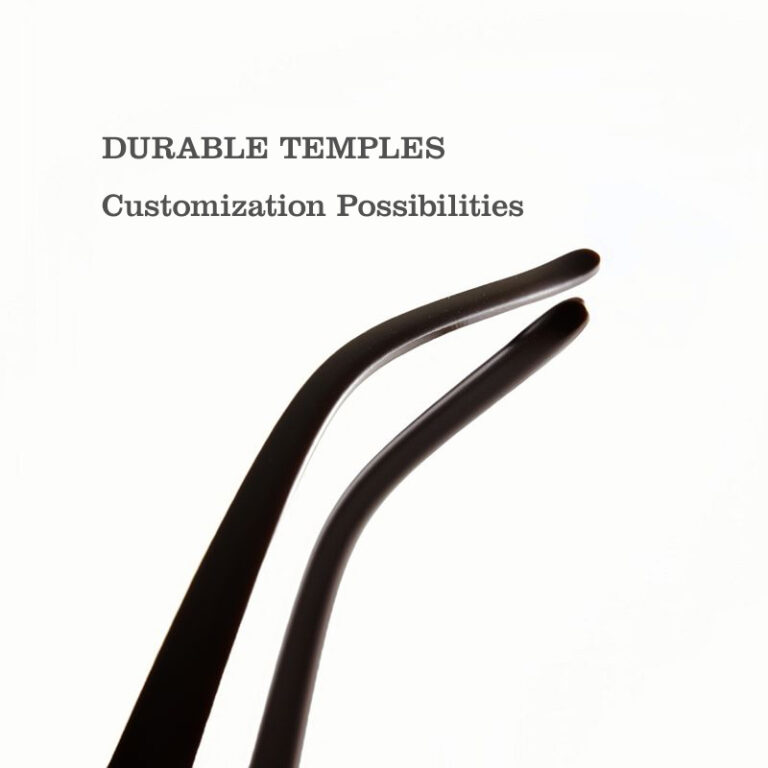

These frames are ideal for wholesale markets and are fully customizable to meet specific client needs. Customization features include:

With a robust OEM and ODM production capacity, the manufacturer ensures high-quality eyewear at competitive prices. The factory’s capabilities include:

To inquire about pricing, quality, minimum order quantities (MOQ), or any other details, please contact us via:

For a faster response, kindly include your WhatsApp number in your message. Whether you need design advice, packaging options, or shipping details, our team is ready to assist.

In an era where digital screens dominate our daily activities, protecting our eyes has never been more important. Prolonged exposure to computer screens can lead to eye strain, fatigue, and even disrupt our sleep patterns due to harmful blue light emission. This is where custom blue blocker glasses for computer use come into play. When choosing the right pair, the lens material is a crucial factor, and polycarbonate lenses stand out as an exceptional choice. Let’s delve into why polycarbonate is the ideal material for your blue-blocking eyewear.

Polycarbonate is a type of durable plastic that’s renowned for its impact resistance and optical clarity. Originally developed for aerospace applications, it’s now a popular material for eyeglass lenses. Polycarbonate lenses are thinner and lighter than traditional plastic or glass lenses, providing comfort without compromising on strength.

One of the standout features of polycarbonate lenses is their high impact resistance. They are up to 10 times more impact-resistant than plastic or glass lenses. This makes them an excellent choice for custom blue blocker glasses for computer use, especially if you lead an active lifestyle or require durable eyewear for work.

Polycarbonate lenses naturally block 100% of harmful UVA and UVB rays, offering full ultraviolet protection. While blue light filters target high-energy visible (HEV) blue light emitted from screens, the added UV protection from polycarbonate lenses ensures your eyes are safeguarded both indoors and outdoors.

Given that many of us spend hours in front of computers, comfort is key. Polycarbonate lenses are incredibly lightweight, reducing the pressure on your nose and ears during extended wear. This makes them ideal for custom blue blocker glasses for computer users who need reliable and comfortable eyewear throughout the day.

Polycarbonate lenses offer excellent optical clarity, providing sharp and clear vision. When combined with a blue light filtering coating, these lenses can significantly reduce glare and enhance contrast. This combination helps alleviate digital eye strain and improves visual comfort during screen time.

While polycarbonate lenses are durable, they are prone to scratches without proper coatings. Most high-quality polycarbonate lenses come with a scratch-resistant coating to enhance their durability. This ensures your custom blue blocker glasses for computer remain clear and free from blemishes, even with regular use.

Polycarbonate lenses are also recyclable, making them an environmentally conscious option. Choosing polycarbonate for your custom eyewear contributes to sustainability efforts by reducing waste and promoting recycling initiatives within the eyewear industry.

When selecting custom blue blocker glasses for computer use, combining polycarbonate lenses with blue light filtering technology offers comprehensive eye protection. The blue light filter reduces exposure to harmful HEV blue light, while the polycarbonate material provides durability, UV protection, and comfort.

Investing in custom blue blocker glasses for computer use with polycarbonate lenses is a smart move for anyone looking to enhance eye comfort and protection during screen time. The unique properties of polycarbonate lenses—impact resistance, lightweight comfort, UV protection, and optical clarity—make them the ideal choice for modern eyewear solutions.

Protect your eyes from the strains of digital life by choosing polycarbonate lenses for your custom blue blocker glasses. Experience the perfect blend of durability, comfort, and advanced eye protection technology.

In the competitive world of eyewear, the packaging of custom glasses frames plays a pivotal role in branding and customer experience. An exceptional packaging not only protects the product but also enhances its appeal, reflecting the quality and personality of the eyewear inside. Let’s delve into some innovative packaging methods that are making waves in the eyeglasses industry.

Bamboo Wood Case: Eco-friendly and elegant, bamboo cases offer durability with a natural touch.

Triangle Folding Glasses Case: Space-saving and stylish, these fold flat when not in use, perfect for the modern minimalist.

Patterned Leather Fashion Glasses Case: Add a luxurious feel with patterned leather, blending fashion with functionality.

Square Trend Tinplate Leather Glasses Case: A chic choice combining tinplate strength with leather sophistication.

Soft Velvet Fashion Glasses Case: Velvet cases provide a plush interior, protecting lenses from scratches.

Unique Printed Four Corner Folding Box: Customize with unique prints to make a memorable brand statement.

Soft Microfiber Eyeglasses Pouches: Lightweight and gentle, microfiber pouches double as lens cleaners.

Lightweight Wooden Glasses Case: For a rustic charm, lightweight wood offers protection without bulk.

Hard Shell PU Leather Stylish Eyeglasses Case: PU leather cases are tough yet trendy, safeguarding in style.

Leather Sunglasses Cases: Timeless and sturdy, leather cases are a classic choice for premium eyewear.

Choose packaging that reflects your brand and meets your customers’ needs. The right case enhances the unboxing experience and sets your eyewear apart in a competitive market.

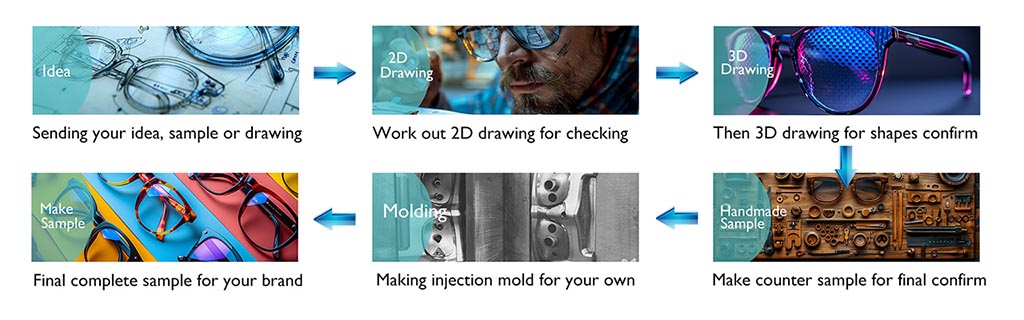

Creating the perfect pair of eyeglasses is a collaborative journey that merges your unique vision with our expertise in design and manufacturing. We have crafted a comprehensive six-step process to ensure that every detail aligns with your expectations, resulting in eyewear that is both functional and stylish. Here’s how we bring your custom glasses to life:

Your journey begins with an idea. Whether you have a rough sketch, a detailed drawing, a photograph, or even just a verbal description, we welcome all forms of inspiration. Share your thoughts on the style, material, and shape you envision. Our dedicated design team will work closely with you to translate these ideas into a tangible concept. This collaborative effort ensures that your creativity is captured accurately, setting a solid foundation for the custom design process.

Once we’ve understood your concept, our designers transform it into a precise 2D technical drawing. This blueprint serves as a detailed visual and dimensional reference, outlining every aspect of the glasses frames structure—measurements, frame thickness, lens size, and other key features. The 2D drawing allows you to review the technical specifications thoroughly. At this stage, you have the opportunity to suggest adjustments or modifications, ensuring that the design aligns perfectly with your expectations before progressing further.

With the 2D blueprint approved, we elevate the design into a 3D model. This three-dimensional representation brings your eyewear to life, showcasing the actual shape, curves, and angles from all perspectives. The 3D model provides an immersive experience, helping you visualize how the frames will look and fit. It also illustrates how different materials interact within the design. This step is crucial for confirming that both the aesthetics and functionality meet your standards before moving into physical production.

After you approve the 3D model, we proceed to create a counter sample—a physical prototype of your glasses frames. Crafted using the materials and specifications outlined earlier, this sample allows you to experience the eyewear firsthand. You can assess the fit, comfort, and overall appearance, ensuring that it not only looks great but also feels right when worn. This stage is vital for making any last-minute tweaks or adjustments before mass production begins, giving you complete confidence in the final product.

With the counter sample finalized, we move on to creating a custom injection mold. This mold is essential for producing your glasses frames in bulk while maintaining high precision and consistency. We incorporate your branding elements directly into the mold, including logos, engravings, or any specific details that embody your brand identity. This integration ensures that every pair manufactured carries the same quality and branded features as the approved sample, providing a uniform and professional finish.

The final step involves producing a complete sample using the injection mold and all integrated branding elements. This fully finished product represents exactly what the mass-produced eyeglasses will be. It includes all design features, materials, and customizations as per your specifications. By reviewing this final sample, you can ensure that every aspect—from the frame shape to the smallest branding detail—has been executed flawlessly. Upon your approval, we proceed with full-scale manufacturing, delivering eyewear that is uniquely yours.

Bringing Your Unique Eyewear to Life

Our meticulous process is designed to prioritize your vision at every stage. By combining your ideas with our technical expertise and attention to detail, we create custom glasses frames that truly reflect your style and meet your functional needs. From the initial concept to the final product, we are committed to delivering eyewear that exceeds your expectations.

We look forward to embarking on this creative journey with you and bringing your unique eyewear designs to reality.

As a leading China-based manufacturer and exporter of high-quality eyeglasses. Nestled in Taizhou, Zhejiang Province, the renowned eyewear hub of China our expansive 6,000 square meter factory is a testament to our commitment to excellence. With over 15 years of industry expertise and a robust production capacity of 800,000 pieces per month, we are dedicated to delivering exceptional eyewear solutions to clients worldwide.

Our focus is on crafting top-quality, iconic designs that resonate with renowned eyewear brands across the globe. We cater to all market segments, providing innovative and customizable eyewear solutions that meet and exceed international safety and quality standards. Our certifications including ISO 9001, CE, FDA, reflect our unwavering dedication to quality and compliance.

We offer professional OEM/ODM services, developing over 300 new models annually. Our diverse product range includes reading glasses, blue light blocking glasses, sunglasses, sports eyewear, kids’ eyewear, and a variety of accessories. Our strong domestic and international partnerships have propelled us to new heights.

Our skilled engineering team collaborates closely with clients to transform ideas and concepts into reality. Whether you’re launching new models or refining existing ones, we provide customized solutions tailored to your unique needs. We strive to meet the evolving demands of modern consumers and the global eyewear market by delivering premium products that blend style, functionality, and durability.

Believe we will be your reliable partner in the eyewear industry. Experience unparalleled quality, innovation, and customer service as we work together to shape the future of eyewear one iconic design at a time.

Selecting the right lens strength is essential for clear vision and comfort. We recommend consulting with an eye care professional to determine your exact prescription. If that’s not possible, you can use an at-home diopter test chart available on our website to estimate the magnification you need based on the smallest text you can comfortably read at a typical reading distance.

We offer a diverse collection of stylish reading glasses for women, including classic, modern, and trend-setting frames. Our selection features various shapes like cat-eye, round, rectangular, and more. With a wide array of colors and materials, you can find the perfect pair that complements your style and personality.

Yes, many of our reading glasses come with blue light blocking lenses. These lenses help reduce eye strain and fatigue by filtering out harmful blue light emitted from digital screens such as computers, tablets, and smartphones. They’re perfect for anyone who spends extended periods in front of screens.

Absolutely! If you have a specific prescription, we offer options to customize your lenses accordingly. When placing your order, simply select the “Prescription Lenses” option and provide the necessary details. Our team will craft lenses that match your requirements and fit them into your chosen frames.

Clean the lenses regularly with a microfiber cloth and lens cleaner.

Avoid using paper towels or clothing, which can scratch the lenses.

Store them in a protective case when not in use.

Keep them away from extreme temperatures to prevent warping or damage.

Yes, we have a selection of reading sunglasses that combine magnification with UV protection. They’re perfect for outdoor reading, allowing you to enjoy clear vision while shielding your eyes from harmful ultraviolet rays. Browse our collection to find styles that suit your preferences.

Yes, we ship to many countries worldwide by Sea, Air, Airexpress. International shipping rates and delivery times vary depending on the destination. Please contact us for more information.

We understand the importance of evaluating product quality before committing to a large purchase. Samples are available upon request, please reach out to our sales team to arrange sample delivery.

Absolutely! As a manufacturer, we provide customization options for frame shapes, colors, materials, and lens specifications. Whether you have a specific design in mind or want to incorporate your brand elements, our team is ready to bring your vision to life.

Yes, we offer competitive pricing and attractive discounts on bulk orders. Our wholesale program is designed to provide you with high-quality reading glasses at cost-effective rates, ensuring a great return on investment for your business.

Our standard minimum order quantity varies depending on the specific product and customization requirements. Typically, the MOQ starts at 300pc. Please contact our sales team to discuss your needs, and we’ll work to accommodate your order size.

We use premium materials such as acetate, stainless steel, titanium, and durable plastics to craft our frames. Our lenses are made from high-quality optical materials that provide clear vision and UV protection, ensuring comfort and safety for the end-users.

Production times depend on the order size and customization level. Standard orders typically take 2-4 weeks to manufacture. Shipping times vary based on the destination. We strive to deliver your products promptly and will provide an estimated timeline when you place your order.

Yes, we offer private labeling and Original Equipment Manufacturer (OEM) services. We can incorporate your brand logo, packaging designs, and any specific requirements you have to ensure the products align with your brand identity.

Didn’t find what you want? Ask our manager for help!

Didn’t find what you want? Ask our manager for help!