Related Products

Find more eyeglasses frames from your realiable partner, contact us if any interest.

The latest advancement in women’s eyewear brings together cutting-edge technology and fashionable design. Our new range of polarized rectangle sunglasses offers not only a chic aesthetic but also superior optical performance, ensuring that you experience the world with clarity and style.

The core of this eyewear’s optical performance lies in its utilization of premium TAC polarized lenses. These lenses are engineered to achieve a polarization efficiency exceeding 99%, effectively eliminating horizontally polarized glare prevalent in outdoor environments. This high polarization efficiency dramatically reduces eye strain and fatigue, while significantly enhancing visual acuity and contrast sensitivity. The spectral transmission characteristics of the lenses are carefully controlled to attenuate harmful ultraviolet (UV) radiation (UVA and UVB) and high-energy visible (HEV) light, thereby safeguarding ocular health and promoting long-term visual comfort. The precise dimensions of the lenses, detailed in Table 1, are optimized to provide a wide field of view and minimal peripheral distortion, catering to the dynamic visual needs of the modern wearer.

Lens and Frame Geometric Parameters (mm)

| Parameter | Value (mm) | Tolerance (±mm) |

| Lens Width | 52 | 0.2 |

| Lens Vertical | 44 | 0.2 |

| Bridge Width | 21 | 0.1 |

| Temple Length | 145 | 0.5 |

| Frame Length | 139 | 0.5 |

The TAC material utilized in these lenses possesses exceptional optical clarity, impact resistance, and dimensional stability, ensuring pristine visual performance and long-term durability. The lenses are further enhanced with a scratch-resistant coating, mitigating surface damage and maintaining optical clarity over extended use. A key characteristic of these lenses is their lightweight nature, contributing to an overall eyewear weight of just 30 grams, a significant factor in enhancing wearer comfort, particularly during prolonged use. Furthermore, the material selection process prioritizes environmentally friendly options, aligning with contemporary consumer values and minimizing environmental impact. The application of a corrosion-resistant spray paint not only enhances aesthetic appeal but also contributes to the longevity of the lenses, preventing degradation from environmental factors. This meticulous attention to material properties ensures that the lenses maintain their flatness, preventing warping or distortion that could compromise optical performance over time. The robust nature of the chosen materials ensures the lenses are not easily broken, offering a reliable and long-lasting eyewear solution. The color stability of the lenses is also a noteworthy attribute, with no fading or deformation observed over extended use, ensuring both consistent performance and aesthetic appeal.

The frame design incorporates a hybrid construction, strategically combining the advantageous properties of TR-90 thermoplastic and cellulose acetate. TR-90, a high-performance polyamide renowned for its flexibility, impact resistance, and lightweight characteristics, forms the primary structural element of the frame. This material provides exceptional resilience to mechanical stress and deformation, ensuring the frame maintains its shape and integrity even under demanding conditions. Cellulose acetate, a bio-based polymer derived from natural sources, is incorporated into the temple arms and decorative elements, offering a luxurious aesthetic appeal and a comfortable tactile experience. This hybrid approach allows for the creation of a frame that is both exceptionally durable and aesthetically refined, catering to both functional and fashion-conscious consumers.

The rectangular frame geometry has been meticulously engineered to provide a comfortable and stable fit for a diverse range of facial shapes, including long, square, and oval profiles. The frame’s dimensions and curvature are optimized to distribute weight evenly across the nose bridge and temples, minimizing pressure points and preventing slippage during dynamic movements. The lightweight nature of the frame, combined with its ergonomic design, ensures that the eyewear remains comfortable even during extended wear. The flexibility of the TR-90 material allows the frame to adapt to subtle variations in facial contours, further enhancing fit and stability. The use of a lightweight yet robust acetate for the temples enhances the overall comfort of the eyewear, providing a secure yet gentle fit around the ears.

The manufacturing process adheres to stringent quality control protocols at every stage, from raw material inspection to final product assembly. Precision injection molding techniques are employed for the TR-90 frame components, ensuring dimensional accuracy and structural integrity. Cellulose acetate components are meticulously fabricated using advanced machining and polishing processes to achieve a superior surface finish and aesthetic appeal. Lenses are precisely cut and edged using automated CNC machinery, ensuring a perfect fit within the frame and optimal alignment of the polarization axis. Each pair of sunglasses undergoes a rigorous visual and mechanical inspection to verify compliance with established quality standards. This includes assessments of lens clarity, polarization efficiency, frame integrity, and overall finish quality.

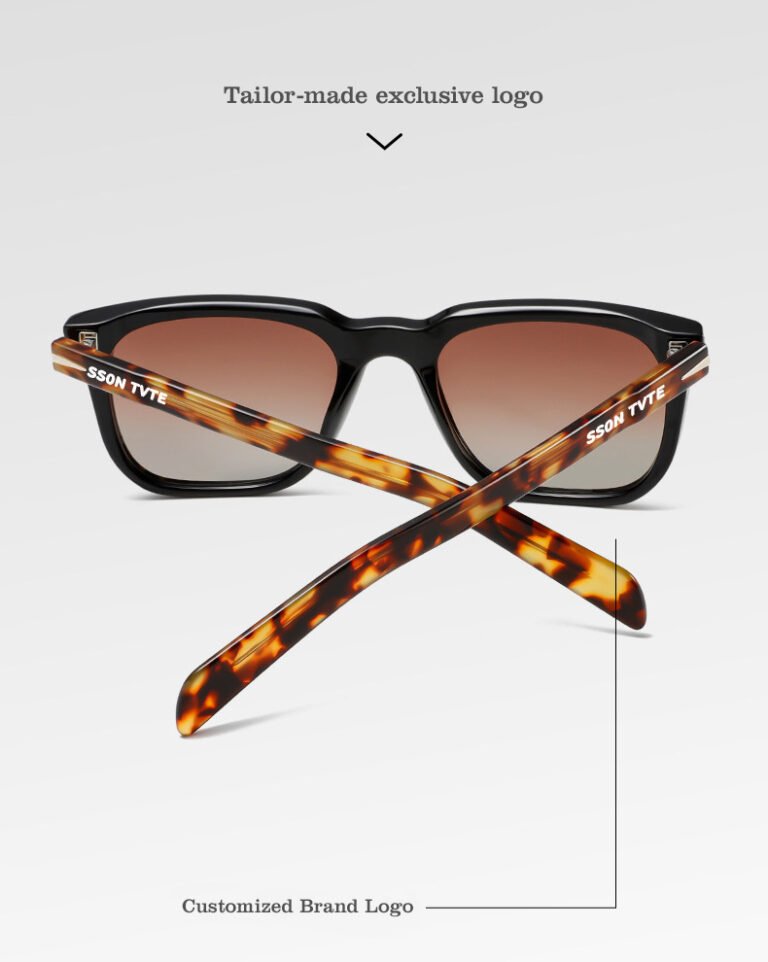

This eyewear model is offered in a curated selection of colorways, including Black/Grey, Brown/Tea, Tortoiseshell/Tea, Clear Green/Gradient Green, and Grey/Gradient Gray, reflecting current fashion trends and consumer preferences. Furthermore, the company offers comprehensive Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services, enabling clients to create bespoke eyewear solutions tailored to their specific branding and market needs. This includes customization options for lens tints, frame colors, and the application of logos or brand identifiers to the lenses and temples. The company possesses significant OEM capability and production capacity, allowing for the efficient fulfillment of both small and large-scale orders. Whether it’s a luxury brand seeking custom wholesale solutions or a retailer looking to develop a unique product line, the company offers a flexible and responsive approach to meeting customer requirements. Printing of logos or brands on lenses and temples is achieved using advanced techniques to ensure durability and aesthetic appeal.

We maintains a well-established supply chain and efficient logistics network, ensuring timely delivery of products to customers worldwide. Both wholesale and bulk manufacturing options are available, catering to a diverse range of clients, from independent boutiques to large retail chains. The company emphasizes transparent communication and responsive customer service, providing detailed information on product quality, pricing, minimum order quantities (MOQs), packaging, shipping options, and safety certifications. Inquiries are promptly addressed through multiple channels, including WhatsApp, email, and online submission forms, with a preference for WhatsApp communication to facilitate real-time interaction and efficient information exchange. The emphasis on readily available stock ensures quick turnaround times for standard orders, while the robust OEM/ODM program supports the development and delivery of customized products within reasonable lead times. This commitment to a responsive and reliable supply chain underscores the company’s dedication to customer satisfaction and long-term partnerships.

This rectangular polarized sunglass model is strategically positioned within the contemporary eyewear market to appeal to fashion-conscious female consumers seeking a blend of style, performance, and value. The design philosophy centers on delivering high-quality, durable eyewear with a fashion-forward aesthetic, offered at a competitive price point. The use of premium materials, advanced manufacturing techniques, and a commitment to quality assurance ensures that the eyewear meets the demanding expectations of discerning consumers. The versatility of the design, suitable for both work and leisure activities, further enhances its market appeal. The company’s commitment to providing both ready-to-wear and customized solutions allows it to effectively cater to a wide range of market segments, solidifying its position as a reliable and innovative supplier within the polarized sunglass industry. The fashion design incorporated into these sunglasses ensures they are not just functional eyewear but also stylish accessories, adding to the value proposition. The reasonable pricing strategy ensures that high quality and fashionable eyewear are accessible to a broad consumer base.

The selection of TR-90 as the primary frame material is predicated on its exceptional mechanical and chemical properties. TR-90, a thermoplastic copolyester, exhibits a high flexural modulus, ensuring the frame maintains its shape and resists deformation under stress. Its low density (approximately 1.14 g/cm³) contributes to the overall lightweight nature of the eyewear, enhancing wearer comfort. Furthermore, TR-90 possesses excellent resistance to chemicals and environmental stress cracking, ensuring long-term durability and resistance to degradation from exposure to sweat, cosmetics, and cleaning agents. The material’s biocompatibility also makes it suitable for prolonged skin contact, minimizing the risk of allergic reactions or skin irritation. Key performance parameters of TR-90 are summarized in Table 2.

Table 2: TR-90 Material Properties

| Property | Value | Unit | Test Method |

| Density | 1.14 ± 0.02 | g/cm³ | ASTM D792 |

| Tensile Strength | 65 ± 5 | MPa | ASTM D638 |

| Flexural Modulus | 2300 ± 200 | MPa | ASTM D790 |

| Impact Strength (Izod Notched) | 80 ± 10 | J/m | ASTM D256 |

| Water Absorption (24 hrs) | < 0.2 | % | ASTM D570 |

| Glass Transition Temperature (Tg) | 140 ± 5 | °C | DSC |

Cellulose acetate, derived from renewable wood pulp or cotton linters, is strategically employed for the temple arms and decorative elements, contributing to both the aesthetic appeal and functional performance of the eyewear. This bio-based polymer offers a luxurious tactile experience and a rich depth of color, unattainable with conventional thermoplastics. Cellulose acetate exhibits excellent dimensional stability and resistance to warping, ensuring that the temple arms maintain their precise fit and alignment over time. Furthermore, it is hypoallergenic and possesses good resistance to UV degradation, preserving its aesthetic qualities and structural integrity even with prolonged exposure to sunlight. The specific grade of cellulose acetate utilized is selected for its high clarity, allowing for the creation of visually appealing temple designs with intricate details and vibrant color patterns.

To ensure optimal structural integrity and durability, the frame design undergoes rigorous Finite Element Analysis (FEA) modeling. This computational technique allows engineers to simulate the frame’s response to various mechanical loads, including bending, torsion, and impact forces. The FEA model incorporates detailed material properties, geometric parameters, and boundary conditions to accurately predict stress distribution and potential failure points within the frame. The results of the FEA simulations are used to iteratively refine the frame design, optimizing wall thicknesses, reinforcing critical areas, and minimizing material usage without compromising structural performance. This process ensures that the frame can withstand the rigors of daily wear and tear, meeting or exceeding industry standards for impact resistance and durability.

Beyond the inherent polarization properties of the TAC lenses, advanced multi-layer coatings are applied to further enhance optical performance and durability. These coatings, typically deposited using vacuum deposition techniques, include:

Anti-reflective (AR) coatings: These coatings minimize surface reflections, increasing light transmission and reducing glare. AR coatings typically consist of multiple layers of dielectric materials with alternating high and low refractive indices, carefully tuned to achieve destructive interference of reflected light across a broad spectral range. The result is enhanced visual clarity, reduced eye strain, and improved contrast sensitivity. Typical reflectance values for AR-coated lenses are less than 1% across the visible spectrum.

Scratch-resistant coatings: A hard, durable coating is applied to the lens surfaces to protect against scratches and abrasions. These coatings typically consist of silicon-based polymers or inorganic materials with high hardness and abrasion resistance. Scratch-resistant coatings significantly extend the lifespan of the lenses, maintaining optical clarity and preventing surface damage from impacting visual performance.

Hydrophobic and oleophobic coatings: These coatings impart water and oil repellency to the lens surfaces, preventing the formation of water droplets, smudges, and fingerprints. Hydrophobic coatings typically consist of fluorinated polymers or silane-based compounds that create a low surface energy, causing liquids to bead up and roll off the lens. Oleophobic coatings provide similar protection against oils and grease, making lenses easier to clean and maintain. The combination of hydrophobic and oleophobic coatings ensures that lenses remain clear and unobstructed, even in challenging environmental conditions.

Our comany dedication to innovation and customer-centric design is evident in the extensive customization options, ergonomic considerations, and meticulous attention to detail throughout the manufacturing process. The ongoing research and development efforts focused on smart eyewear integration, advanced materials, and personalized solutions position the company at the forefront of the eyewear industry, poised to meet the evolving needs and expectations of consumers in the years to come. The future of eyewear is bright, with continued advancements promising to deliver enhanced visual experiences, personalized comfort, and a deeper integration with our increasingly connected world.

Our acetate eyeglasses frames are crafted from high-quality cellulose acetate, a durable and flexible material derived from natural cotton and wood fibers. This premium material allows for vibrant colors and patterns, providing both style and longevity.

Acetate frames offer several advantages:

Durability: Resistant to wear and tear, ensuring long-lasting use.

Lightweight Comfort: Provides comfortable all-day wear without pressure.

Hypoallergenic: Ideal for sensitive skin, reducing the risk of irritation.

Versatile Designs: Available in a wide array of colors, patterns, and styles.

Yes, we specialize in custom designs for wholesale orders. You can personalize frame shapes, colors, finishes, and even add your brand logo. Our design team works closely with you to bring your unique vision to life.

Our standard MOQ is 1200pc, but we offer flexibility depending on your specific needs. Please contact our sales team to discuss your requirements.

Production time typically ranges from 35-45 days depending on the complexity and quantity of your order. Shipping times vary by location but generally take 35 days. We prioritize timely delivery without compromising quality.

Quality is our top priority. Our frames undergo strict quality control at every production stage. We comply with international standards and ensure each product meets our rigorous durability and safety criteria.

Rimless titanium glasses frames are known for their minimalist design and lightweight feel. While titanium itself is a durable material, the lack of a full frame does make rimless glasses more susceptible to damage if handled roughly or dropped. However, with proper care and maintenance, rimless titanium glasses can still provide long-lasting wear and remain a stylish choice for those who prefer a more understated look.

Absolutely. We offer sample frames so you can assess the quality and design firsthand. Please reach out to us to arrange sample requests.

Yes, our acetate is made from renewable resources, making it an environmentally friendly choice. We are committed to sustainable practices throughout our manufacturing process.

Yes, we ship worldwide. Our logistics partners ensure secure and efficient delivery to your specified location. Shipment through by Air, Sea FCL/LCL, Air Express, FedEx, DHL etc, and by Train.

You can contact our sales team via Contact Form Link. Provide details about your desired products, and we’ll offer a tailored quote promptly.

Yes, our experienced design team can collaborate with you to develop custom frames based on your concepts. From initial sketches to final prototypes, we’re here to help bring your ideas to fruition.

Yes, we offer branding services, including custom packaging and labeling, to enhance your product presentation and strengthen your brand identity.

We combine exceptional craftsmanship with personalized service. Our commitment to quality, sustainable materials, and client satisfaction distinguishes us in the wholesale acetate eyewear market. Through our commitment to competitive pricing and unwavering quality, we are poised to become the preferred choice of customers, gradually eclipsing our competitors.

Find more eyeglasses frames from your realiable partner, contact us if any interest.

Didn’t find what you want? Ask our manager for help!

Didn’t find what you want? Ask our manager for help!